Dear Puzzler Friends,

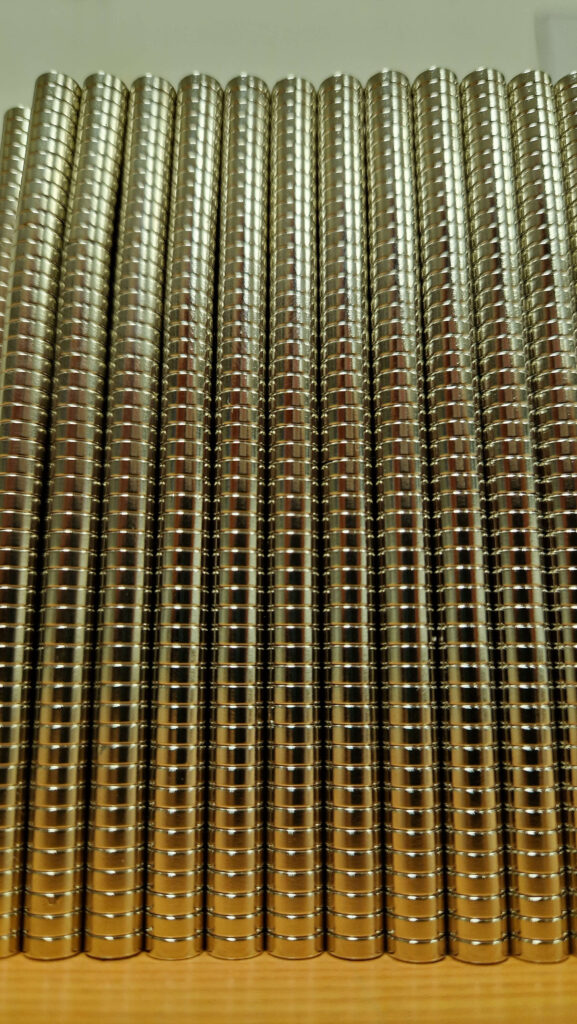

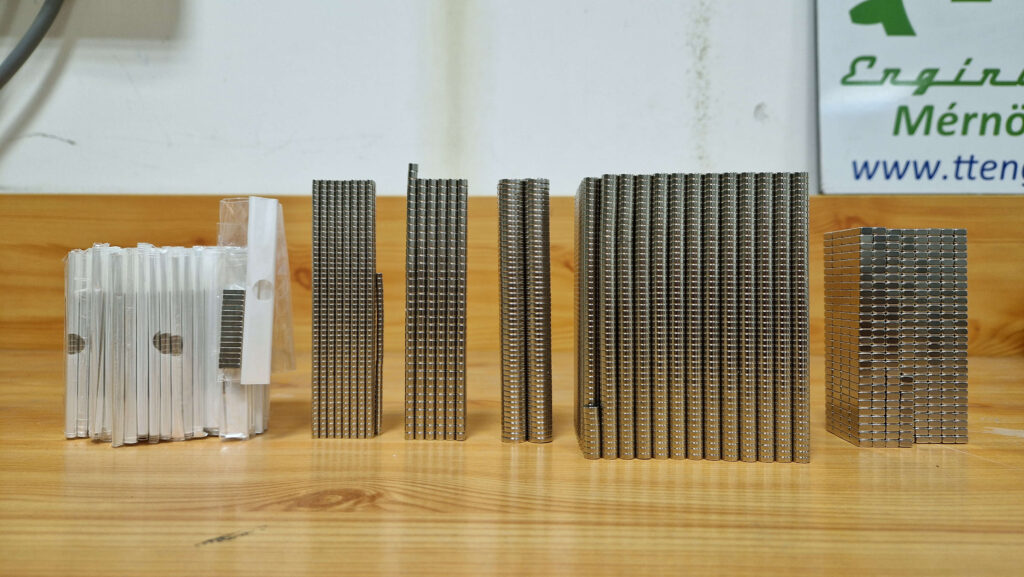

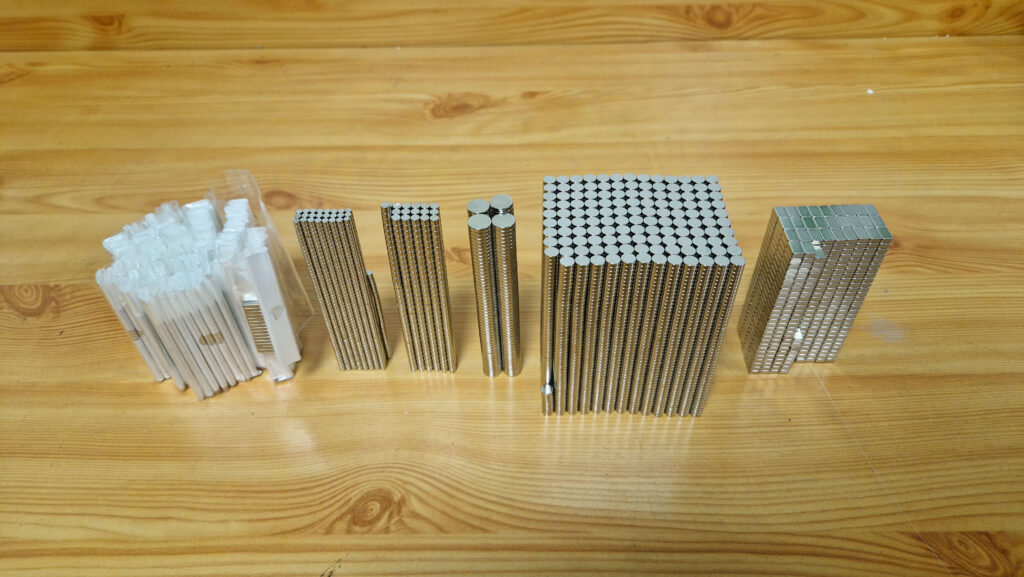

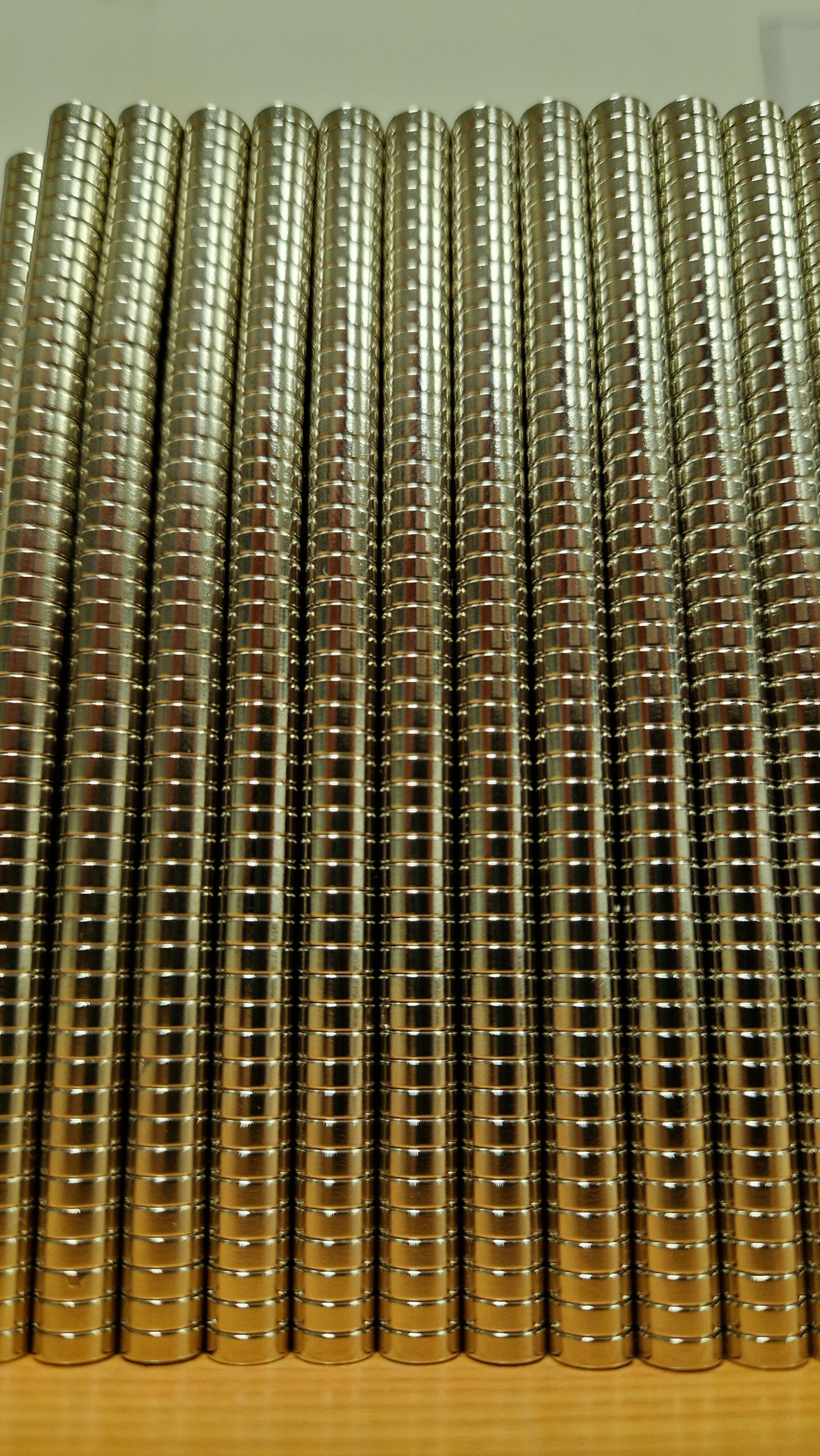

Jukebox production is on fire! Mass production of the various components is currently underway, while at the same time high-gloss mechanical polishing has already begun too. I am transporting parts and pieces between the CNC workshop and the mechanical polishing station on a weekly basis. These are located in our greater neighbourhood. As is usually the case with serial production, a few obstacles have been encountered. Most of them have already been resolved, one of them is currently being addressed. The ones resolved were minor issues with fine-tuning micro-tolerances, to ensure that all mechanisms work as they should. We are currently brainstorming about finding a viable method to remove polish paste from angled regions and small holes of the several hundreds of pieces, which cannot be performed in a cost-effective way manually. A thorough paste removal is crucial before the anodizing and nickel-plating phases, so that the treated surfaces will be finished homogeneously. We have tried various methods with only partial success. It is somewhat tricky to get rid of the excess paste, whilst also preserving the high-gloss finish, the fine result of mechanical polishing. We are now negotiating with a skilled team using ultrasound-aided cleansing workstations and industrial facility for the thorough removal of polish paste. All in all, a few weeks of slippage in our schedule has caused us to decide not to split production into smaller batches, but rather to aim at delivering the first ~100 units in a single batch. Realistically, this is only to be expected in the first quarter of the next year. I am aware that a November shipment of a small batch was mentioned in the previous blog post, but rather than pushing our limits to deliver the first puzzles in a rush before the Festive season, our main goal remains to perfect every single copy of Jukebox to a quality level equal to (or higher than) the award winning IPP model of the puzzle. The patience and understanding of our customers are very much appreciated. Our team works really hard to ensure that the overall time schedule of the project will not be compromised and the last puzzle will be shipped out latest mid 2025. For now, I enclose a few photos of some pre-ordered accessories (10k plus neodymium magnets, 200 chamois leather clothes) and some freshly polished, high-gloss finished parts in plastic bags. I am being careful not to include any spoiler photo that shows too much of the internals. I hope to be able to post photos of the anodizing and nickel-plating phases soon. The design and prototype of the protective packaging are now also ready for serial production. The boxes are made locally by a professional packaging company in my hometown, Debrecen. I am very pleased with the showcasing feature of the box, and am curious to find out how our customers will like the environmentally friendly design that we have put together.

All in all, this is an extremely exciting time in my life and I cannot be thankful enough to each and every one of our customers who have placed their trust in our product. As I write this blog post, there are only 42 of the limited edition batch of max. 200 puzzles available, which is definitely beyond our expectations 🙂

Until the next blog post, I wish you all the best!

Cheers,

Daniel

MoonTree Puzzles